プロダクト

アプリケーション

関連: ケミカル・触媒

触媒材料の化学的・構造的理解

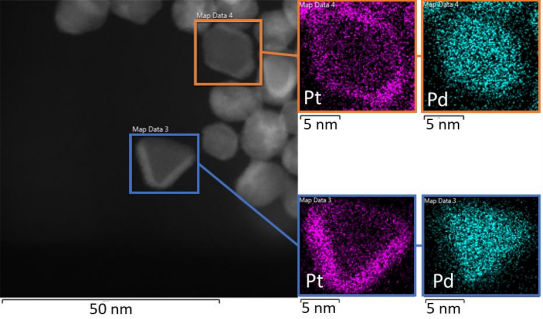

Catalysts are almost as diverse as the chemical reactions that they catalyse. They are, however, crucial in many different technologies from vehicle emission control systems to fuel cells. Understanding the size, structure and elemental composition of these materials is key to understanding their effectiveness as catalysts. Bi-metallic nanoparticles are often used as catalysts, especially in emission control systems, as they have high surface area and enable increased catalytic activity. Exactly how much the reaction rate is increased can vary with the many different properties of these particles, therefore, it is important to have a technique that can correlate these and enable a better understanding of the reaction processes. Using X-ray energy dispersive spectroscopy (EDS) in the electron microscope allows correlation of particle size and shape with its elemental composition.

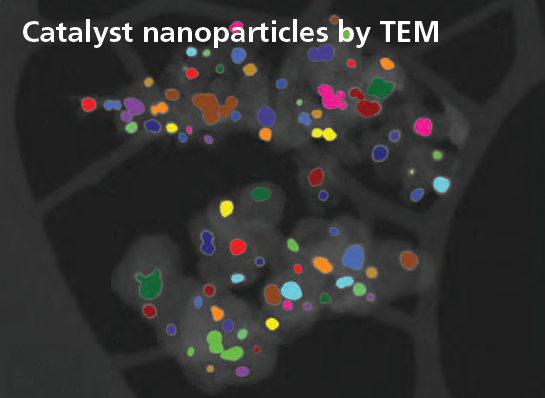

Using AZtecFeature particle analysis software and high sensitivity X-Max and Ultim Max EDS analysis can be automated for improved throughput while all the important parameters of the particles are stored for classification by and further investigation. In the transmission electron microscope (TEM) the extreme sensitivity offered by two X-Max EDS detectors combined with the spatial resolution of the microscope allows the elemental distribution to be mapped in single particles.

In modern devices such as fuel cells, a number of catalysts and structures are combined to improve efficiency, for example, metallic nanoparticles supported on zeolites to allow the ion trapping functionality of the zeolites to combine with the redox reaction enhancing nature of the Metallic particles. For these systems understanding composition, in-situ is key to understanding. Ultim Extreme EDS for the scanning electron microscope (SEM) allows analysis of both zeolite and particles simultaneous without damaging the typically beam sensitive zeolite.